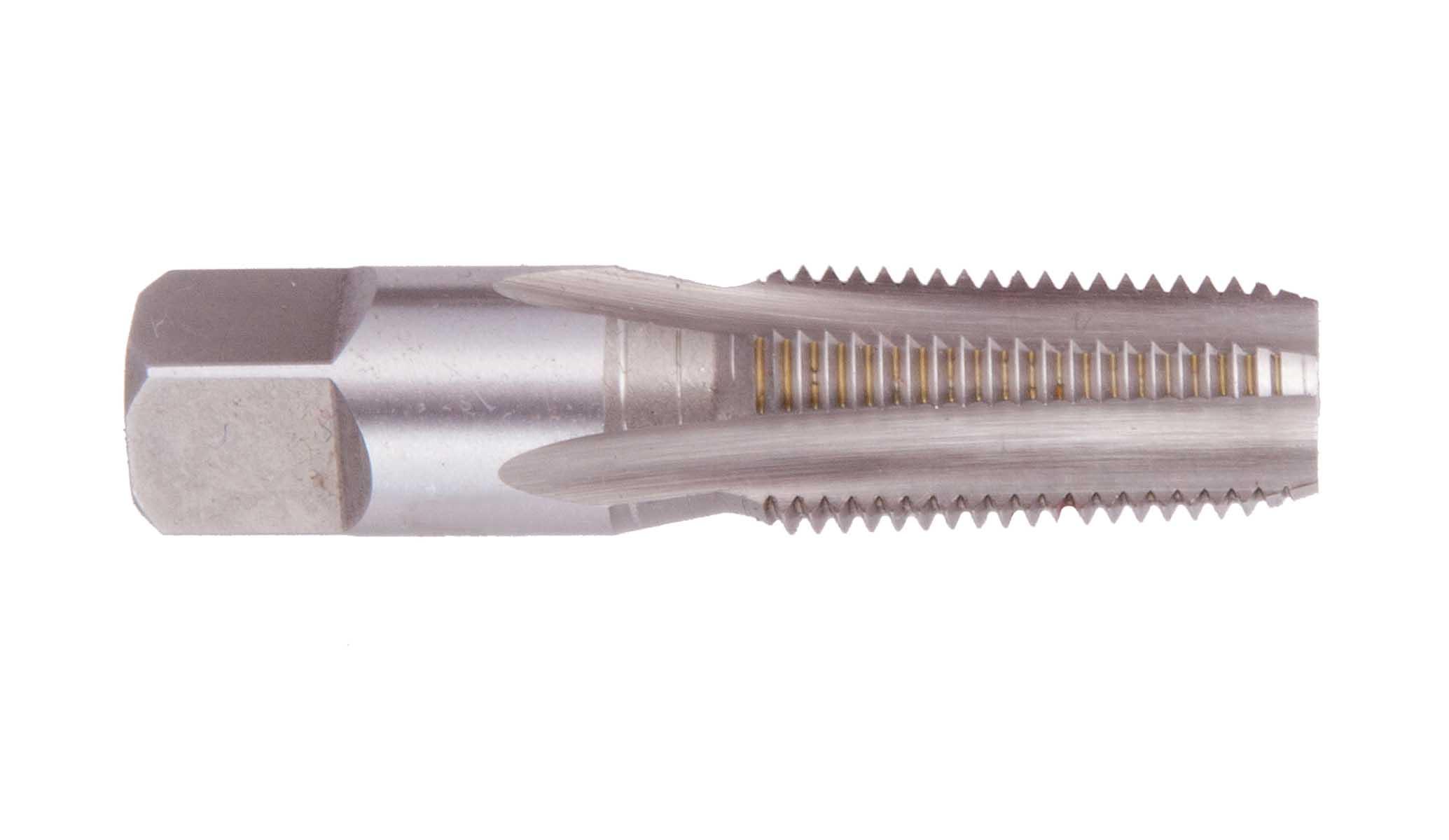

NPT Taper Pipe Taps

NPT (American National Standard Taper) taps for general purpose use in a variety of materials conforming to ANSI standards are available.

Regal proudly carries a variety of NPT taps for general purpose use in a variety of materials conforming to ANSI standards.

Our NPT taps comply with all standards and specifications and are produced from the highest quality steel and carbide to meet your manufacturing needs.

Features of Our NPT Taper Pipe Taps Include:

- Produces threads which conform to the American National Standard Taper Pipe Thread dimensions

- Manufactured to Table 311 standards

- Good for carbon and leaded steels as well as die-cast parts

- High hook specially designed for stainless steel

- Low angle specially designed for cast iron

NPT threads (or National Standard Pipe Thread) are the technical standard for screw threads in the United States, most frequently used in threaded pipes and pipe fittings.

Of all of the types of threads (NPS, NPTF, etc.), NPT threads are used the most commonly in this country. (Outside the U.S., British Standard Pipe threads are used more regularly.)

Understand the key differences between NPT and NPTF taps.

NPT tap threads can be either tapered or straight, depending on the job at hand. The taper on NPT pipe taps means a seal is tightly formed when correctly torqued. This is due to the flanks of the threads compressing securely against each other (unlike straight thread fittings where the threads hold together without providing that tight seal).

NPT taps produce threads that do require sealant when joined to an external NPT threaded part. Pipe joint compounds (also known as pipe sealant) seal tightly threaded pipe fittings and prevent any leak path along the thread.

There are three kinds of pipe sealants: pipe dope, anaerobic resin compounds and teflon tape. Each sealant has its own special properties, depending on the project.

Tapered pipe tapping is a technique of making internal thread surfaces that will not leak after assembly, even under pressure. Every time the tap revolves, the taper of the tap drives deeper into the hole, making a designated type of cut.